3D printed drone – how to build your own?

Piotr Domanowski - 5th of March 2024

Do you want to 3D print your own drone and you wonder if it even makes sense? If so, in this article you’ll find everything you need to know to build your own 3d printed drone. You’ll also find examples and a ready-to-print underwater drone, fully designed by us.

3D printing technology is now used by various industries for rapid prototyping – for testing pre-production prototypes. But with this technology making its way into our homes, it is also possible to create “one-offs”. These are devices, which are not necessarily optimised for efficient production process – they are just meant to work perfectly, in your one-off prototype. That’s why we can sometimes get away with using 3D printing for drone production. If you only make one drone, or even just 10 drones – 3D printing is a perfect technology to start you off!

Why do 3D printed drones make sense?

You might be tempted to think that 3D printing drones is not very practical. That’s not true. Let’s go through some arguments for why this is not the case.

To start with, 3D printing allows you to have an almost complete geometric freedom with your designs. You can create a production quality drone with every shape and curve you want. You can’t create such complex and beautiful shapes with any other manufacturing method.

If you know your 3D printing filaments and you are willing to modify your printer to start printing with more “extreme” materials, you can also create very durable frames for drones, with materials like Nylon or Polycarbonate.

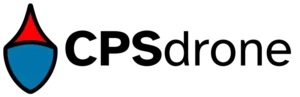

The most important upside for using 3D printing to build drones is how easy it is! You can get good 3D printers for about $500 dollars now and producing your own drone parts is as easy as designing your parts and clicking a button on the printer!

How to start with your first 3D printed drone?

To start 3D printing your own drones, you will need a good drone frame 3D model, which is well-optimized for 3D printing. You need to design a frame, which will not break under the required load, your shape needs to be tuned in very-well, so that you can easily remove support material and the printing process can go without any problems. And then you need to print it.

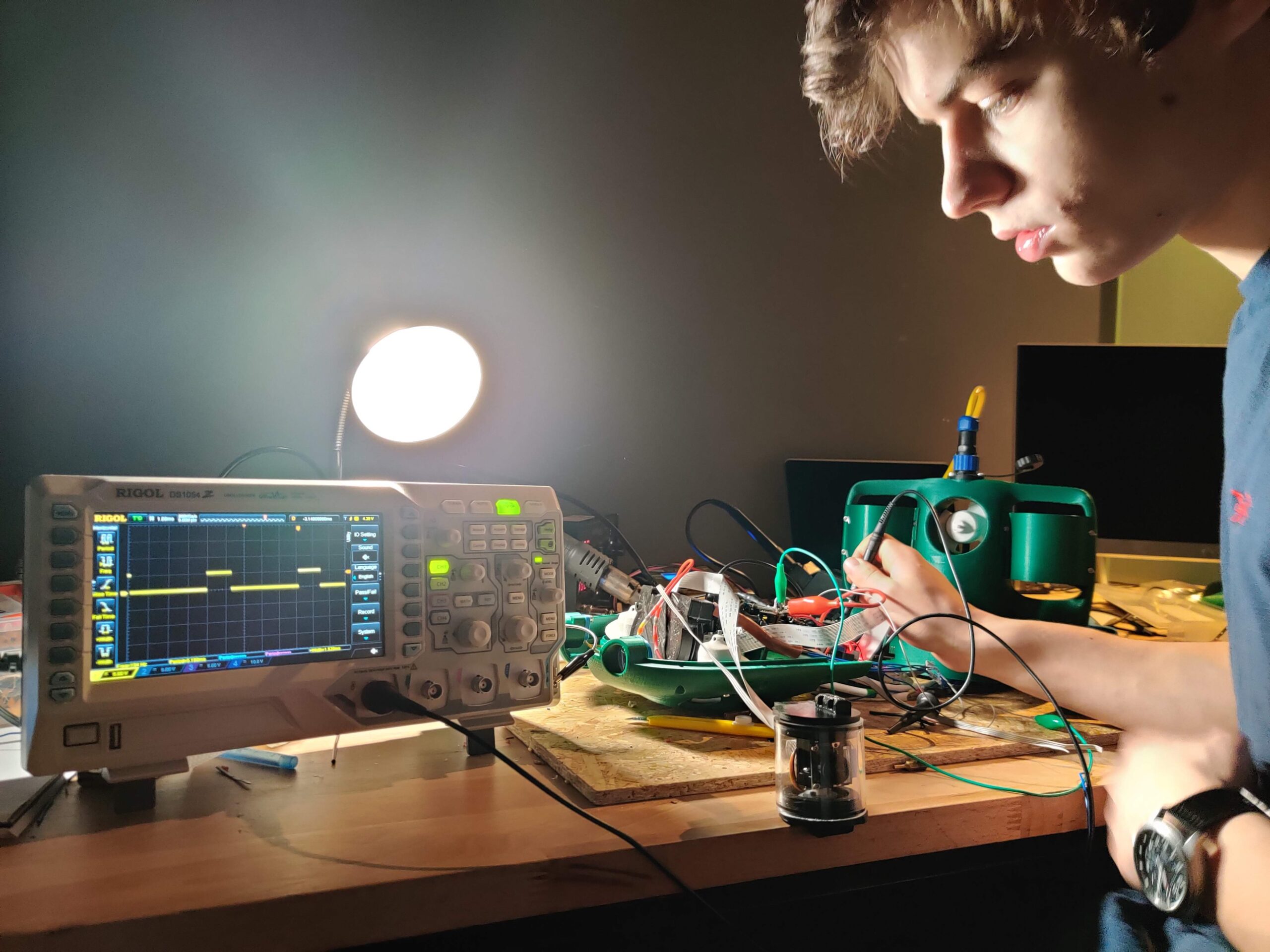

The hardest part of 3D printing your drone is likely not 3D printing itself. Even building the simplest drone, requires at least basic knowledge of communication protocols, electronics, batteries, RC equipment knowledge, motors etc. In my opinion this is the hardest part, mainly because it’s hard to even be aware of what you should learn.

So, to 3D print your own drone, you either need a lot of experience or a very good tutorial. After 3D printing a drone using a tutorial, you’ll get most of the necessary knowledge to design the next drone completely by yourself.

If you’re looking for a practical example, you can check out a YouTube video, which we have made in which we showcase the building process of the fully 3D printed drone – CPS 5 underwater drone, which we have designed ourselves:

Drawbacks of using 3D printing for drones

As with any other technology, 3D printing is not perfect. There are some quite convincing arguments for why would you want to stick to other manufacturing methods for drone production.

The most important argument is that if you’re using regular FDM printers and filaments, your prints will be much weaker than carbon fiber or injection molded plastics. Also, FDM 3D printing tends to create parts which are not uniform. They are weaker in some areas of the print more than in other areas. You should theoretically test your parts before you assemble your drone to make sure they are not a safety-hazard.

That’s why, if you’re planning to scale your drone production with 3D printing, you’ll have a hard time with that. In that case, there are just simply more time-efficient manufacturing methods (like injection molding).

What's required to start with your first 3D printed drone?

Of course, when we are talking about 3D printed drones, we’re mainly considering printing the frame of your drone, the outer shell. You can also print some electronics holders inside of your case. But there’re quite a lot of other parts and tools which are involved to set-up a usable drone building setup.

First off, most 3D printed drone projects don’t require very specialized tools. Basic hand-tools, like drills, soldering irons, screwdrivers, LiPo battery chargers is about everything you need to start tinkering.

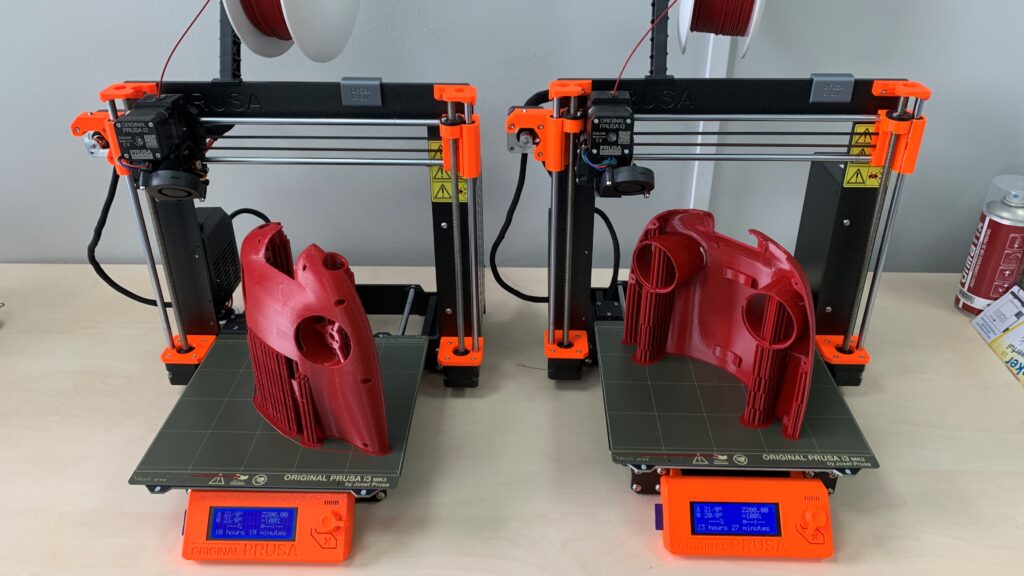

When it comes to the components you’ll use, this depends on the type of drone you want to 3D print. Is it a flying drone, an RC car or maybe a submarine? All of these will require different components rated for different working conditions. Most drones however will require you to get the following parts: batteries, motors, wires, flight controllers, propellers, cameras, ESCs, RC transmitters.

If you’re feeling overwhelmed by this, don’t worry. Most of the tutorials available online list all required parts in a Bill of Materials required for the build. Now, if you are interested in building a fully 3D printed underwater drone called the CPS 5, sign up for a free training below and you’ll get our free Bill of Materials with tools, components & supplies required to get started. After you’re done with this short training, you’ll know everything there is to know about the building process of the CPS 5 drone.

INCLUDED: THE CPS 5 COMPONENT CHECKLIST (BOM)

When you register for the free CPS 5 training, we will send you the Bill Of Materials for free, which lists everything you’ll ever need when building the CPS 5 drone.

How hard is to 3D print a drone?

After you have completed a couple of projects, designing and 3D printing your own drones becomes much easier, just because you start noticing that all the builds are actually built on the same foundations.

If you’re starting without any tutorial though, trying to design your own drone from the very start, you’ll probably have a bit of hard time. When we were starting out, we wanted to build an underwater drone without any comprehensive tutorial whatsoever. We have only watched random websites and YouTube videos to answer all the questions we had. Because of our approach, it took us about 2 years to complete our very first 3d printed drone – you can do it much faster!

Let’s start with your first 3D printed drone!

If you want to start 3D printing your own drones, you are in the right place. The CPS 5 online course, which we are teaching will teach you everything you need to know to build a fully 3D printed underwater drone. The course contains explanations about the design, electronics, motors, propellers, making the drone waterproof, 3D printing for underwater technologies and much more!

After this course, you’ll not only have an adventure ready underwater drone but also knowledge about how to design your next 3D printed drone projects.

Click the link below to sign-up for a free training and get started with the CPS 5 course.

NOW IT’S YOUR TURN TO BUILD YOUR OWN DRONE!